Industrial Vacuum Pumps Explained

Types of Vacuum Pumps, Applications, and Service Considerations

Industrial vacuum systems are critical to many manufacturing and processing operations. From material handling and packaging to chemical processing and degassing, vacuum pumps enable processes that would otherwise be impossible. Selecting the correct vacuum pump technology—and maintaining it properly—has a direct impact on reliability, energy efficiency, and product quality.

Innovative Oil Solutions offers service and maintenance for industrial vacuum pump systems, supporting a wide range of manufacturers and technologies. Our team helps customers maintain proper vacuum levels, improve system reliability, and prevent costly failures through expert service and preventative maintenance.

What Is an Industrial Vacuum Pump?

A vacuum pump removes gas molecules from a sealed volume to create a vacuum. Industrial vacuum pumps are designed to operate continuously or intermittently while maintaining specific vacuum levels depending on the application.

Vacuum pumps are commonly categorized by:

- Vacuum level (rough, medium, high)

- Pumping mechanism

- Whether oil is used in the compression process

Types of Industrial Vacuum Pumps

1. Rotary Vane Vacuum Pumps (Oil-Sealed)

How They Work Rotary vane pumps use rotating vanes inside a cylindrical housing to compress and discharge gas. Oil is used for sealing, lubrication, and cooling.Common Applications- Packaging and food processing

- CNC hold-down and machining

- Printing and paper processing

- Medical and laboratory equipment

- Reliable and well-understood technology

- Good vacuum levels for most industrial needs

- Compact design

- Requires oil changes and filtration

- Risk of oil contamination

- Not ideal for wet or dirty processes

2. Liquid Ring Vacuum Pumps

How They Work Liquid ring pumps use a rotating impeller and a liquid seal (usually water) to create vacuum. They are tolerant of vapor and liquids in the process stream.Common Applications- Chemical processing

- Pharmaceutical manufacturing

- Food and beverage

- Power generation

- Pulp and paper

- Handles wet, dirty, or corrosive gases

- Cool operating temperatures

- Reliable in harsh environments

- Lower efficiency

- Requires liquid management

- Higher operating cost

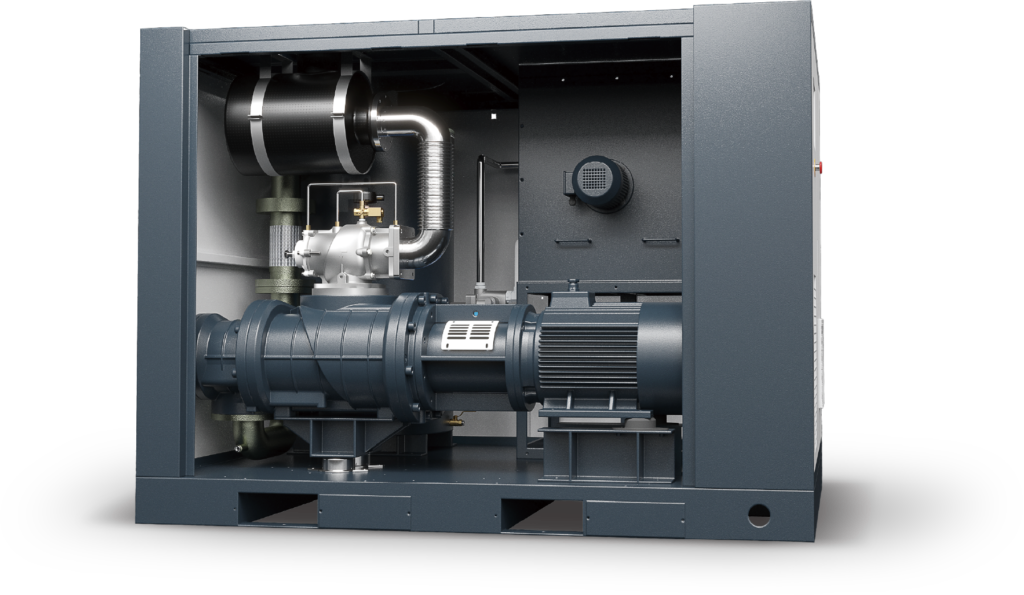

3. Dry Screw Vacuum Pumps

How They Work Dry screw pumps use two intermeshing screws to compress gas without oil in the compression chamber.Common Applications- Semiconductor manufacturing

- Chemical and petrochemical processing

- Pharmaceutical production

- Coating and vacuum drying

- Oil-free vacuum

- High efficiency

- Excellent process cleanliness

- Higher capital cost

- Sensitive to particulates without proper filtration

4. Claw Vacuum Pumps

How They Work Claw pumps use two claw-shaped rotors that compress gas internally without contact or lubrication in the vacuum chamber.Common Applications- Packaging

- Pneumatic conveying

- Woodworking

- Centralized vacuum systems

- Oil-free operation

- Energy efficient

- Low maintenance

- Limited ultimate vacuum compared to oil-sealed pumps

- Higher upfront cost

5. Roots (Booster) Vacuum Pumps

How They Work Roots pumps are not stand-alone vacuum pumps. They are used as boosters in combination with another vacuum pump to increase pumping speed.Common Applications- Large vacuum systems

- Central vacuum networks

- Industrial drying and degassing

- High throughput

- Improves system performance

- Requires backing pump

- Increased system complexity

6. Diaphragm Vacuum Pumps

How They Work Diaphragm pumps use flexible diaphragms to create vacuum without oil.Common Applications- Laboratories

- Medical equipment

- Small analytical systems

- Oil-free

- Clean and quiet operation

- Limited capacity

- Not suitable for large industrial processes

Choosing the Right Vacuum Pump for the Application

Vacuum pump selection depends on:

- Required vacuum level

- Gas composition

- Presence of liquids or contaminants

- Duty cycle

- Energy efficiency goals

Incorrect selection often leads to:

- Excessive energy consumption

- Premature wear

- Frequent failures

- Inconsistent vacuum levels

Service and Maintenance Considerations

Vacuum pumps require proactive maintenance to prevent costly failures.

Typical service includes:

- Oil changes and filtration (oil-sealed pumps)

- Seal and bearing inspection

- Cooling system maintenance

- Vibration and temperature monitoring

- Performance testing

Preventative maintenance significantly extends equipment life and improves system reliability.

Why Vacuum Pump Service Matters

Poorly maintained vacuum pumps can cause:

- Loss of vacuum

- Product quality issues

- Increased energy consumption

- Catastrophic failures

Routine inspections and expert service help avoid downtime and protect production schedules.

Innovative Oil Solutions: Vacuum Pump Service Experts

Innovative Oil Solutions supports a wide range of industrial vacuum pump technologies and manufacturers. Our technicians provide inspections, repairs, rebuilds, and preventative maintenance programs designed to maintain proper vacuum levels and reduce operating cost.

We help customers extend equipment life, improve efficiency, and eliminate unplanned downtime.

Keeping Vacuum Systems Reliable

Industrial vacuum systems are essential to modern manufacturing and processing. With proper pump selection, system design, and ongoing maintenance, these systems deliver reliable performance and long service life.

Innovative Oil Solutions provides the expertise and support required to keep vacuum pump systems operating at peak performance.