Compressed Air Systems: Preventative vs Corrective Maintenance

How Environment, Temperature, and Air Quality Impact Equipment Life and Service Intervals

Compressed air systems are among the most critical—and most abused—utilities in industrial operations. Compressors, dryers, filtration, and downstream equipment often operate continuously in harsh environments, yet maintenance strategies are frequently based on generic service intervals rather than real-world operating conditions.

At Innovative Oil Solutions, we deliver both corrective repairs and proactive preventative maintenance programs designed to reduce downtime, control operating costs, and extend equipment life. Our factory-trained technicians support all major compressor and air treatment technologies, providing scheduled maintenance, emergency service, and 24/7 mobile technical support.

This guide explains how compressor type, air treatment equipment, ambient temperature, contamination, and oil degradation all affect service intervals—and why environment-specific maintenance planning is essential.

Compressor Types and Maintenance Considerations

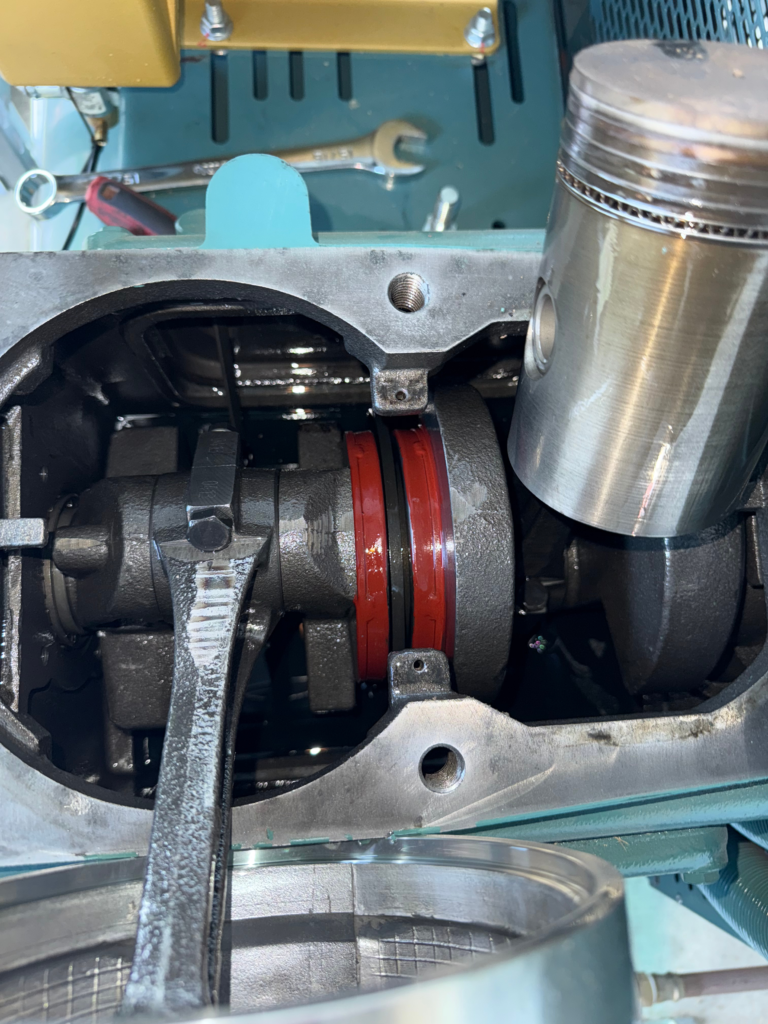

Reciprocating (Piston) Compressors

Reciprocating compressors rely on pistons, valves, and rings, making them highly sensitive to heat and contamination.

Key Maintenance Items

- Valve inspection and replacement

- Piston ring wear

- Oil condition

- Cooling airflow

Environmental Impact

- High ambient temperatures accelerate valve carbonization

- Dirty environments increase intake contamination

- Elevated discharge temperatures shorten oil life

Typical Service Intervals

- Clean indoor environment (≤80°F): 500–1,000 hours minor service

- Hot or dirty environment (≥95°F): 250–500 hours recommended

Rotary Screw Compressors (Oil-Flooded)

Rotary screw compressors depend heavily on oil for lubrication, sealing, and heat transfer.

Key Maintenance Items

- Compressor oil

- Oil and air filters

- Air/oil separator

- Coolers and ventilation

Environmental Impact

- Ambient temperatures above 95°F significantly increase oil oxidation

- Dirty air shortens filter life

- Plugged coolers cause elevated discharge temperatures

Typical Service Intervals

- Clean indoor, climate-controlled room:

- Oil & filters: 2,000–4,000 hours

- Hot, dusty, or outdoor installations:

- Oil & filters: 1,000–2,000 hours

- Separator life reduced by 30–50%

Oil-Free Screw and Centrifugal Compressors

Oil-free compressors eliminate oil carryover risk but require precise temperature control and clean intake air.

Key Maintenance Items

- Inlet filtration

- Cooling systems

- Bearings and seals

- Control calibration

Environmental Impact

- High ambient temperatures reduce efficiency and increase wear

- Dirty environments drastically shorten inlet filter life

Typical Service Intervals

- Clean environment: Standard OEM intervals

- High-temp / dirty environment:

- Inlet filters may require replacement 2–3× more frequently

Air Treatment Equipment and Environmental Effects

Refrigerated Air Dryers

Refrigerated dryers are heavily influenced by ambient temperature and airflow.

Key Maintenance Items

- Condenser cleanliness

- Refrigeration compressor runtime

- Drain operation

Environmental Impact

- Ambient temps above 95°F reduce cooling efficiency

- Dirty environments plug condensers, increasing energy use

Service Interval Impact

- Clean indoor: Annual service often sufficient

- Hot/dirty: Quarterly inspections recommended

Desiccant Air Dryers

Desiccant dryers are highly sensitive to oil contamination and moisture load.

Key Maintenance Items

- Desiccant condition

- Valves and controls

- Pre- and post-filtration

Environmental Impact

- High temperatures increase moisture load

- Poor filtration fouls desiccant rapidly

Service Interval Impact

- Clean systems: Desiccant life 3–5 years

- Dirty or poorly filtered systems:

- Desiccant failure in 12–24 months

Filtration Systems

Filters are the first line of defense but are often the most neglected.

Filter Life Factors

Ambient dust levels

Compressor intake location

Temperature and humidity

Typical Filter Life Comparison

| Environment | Filter Life |

|---|---|

| Clean indoor | 2,000–4,000 hrs |

| 95°F+ dusty | 500–1,500 hrs |

Dirty filters increase:

Pressure drop

Energy consumption

Compressor operating temperature

Oil Breakdown: Heat Is the Enemy

Oil life is temperature-dependent, not time-dependent.

General Rule of Thumb

For every 18°F (10°C) increase above ideal operating temperature, oil life is reduced by 50%

Examples

185°F oil temp → Normal oil life

203°F oil temp → 50% oil life

221°F oil temp → 25% oil life

High ambient temperatures, dirty coolers,

and restricted airflow accelerate:

Oxidation

Varnish formation

Bearing and rotor wear

Preventative Maintenance vs Corrective Repairs

Preventative Maintenance (PM)

Planned service based on actual operating conditions, not just OEM minimums.

Benefits

- Predictable costs

- Extended equipment life

- Reduced emergency failures

- Improved energy efficiency

Typical PM Activities

- Oil and filter changes

- Cooler cleaning

- Vibration analysis

- Performance trending

Corrective Repairs

Reactive service performed after failure occurs.

Risks

- Production downtime

- Expedited parts costs

- Secondary equipment damage

- Safety exposure

Corrective repairs often cost 3–5× more than preventative maintenance.

Why Environment-Specific Maintenance Matters

A compressor running:

- Indoors at 75°F

- Clean intake air

- Proper ventilation

…will have dramatically different service needs than one:

- Outdoors at 95–110°F

- In dust, oil mist, or chemicals

- With restricted airflow

Using the same maintenance interval for both leads to:

- Premature failures in harsh environments

- Over-maintenance in clean ones

Innovative Oil Solutions: Maintenance Built Around Reality

Innovative Oil Solutions does not believe in one-size-fits-all service schedules. We design preventative maintenance programs based on:

Ambient temperature

Air quality

Duty cycle

Equipment type

Failure history

Our services include:

Scheduled preventative maintenance

Corrective and emergency repairs

Oil analysis and contamination control

Dryer and filtration optimization

24/7 mobile technical support

Keeping Critical Systems at Peak Performance

Compressed air systems only perform as well as their maintenance strategy. Understanding how temperature, contamination, and oil degradation affect service intervals allows facilities to reduce downtime, control costs, and extend equipment life.

Innovative Oil Solutions partners with customers to move beyond reactive maintenance and toward a reliability-focused approach—keeping critical systems operating safely, efficiently, and predictably.