Industrial Blowers Explained: Positive Displacement Blowers and Applications

Industrial blowers are critical to processes that require consistent airflow, controlled pressure, and reliable operation. From wastewater aeration to pneumatic conveying and combustion air, blower systems play a vital role in maintaining production efficiency and uptime.

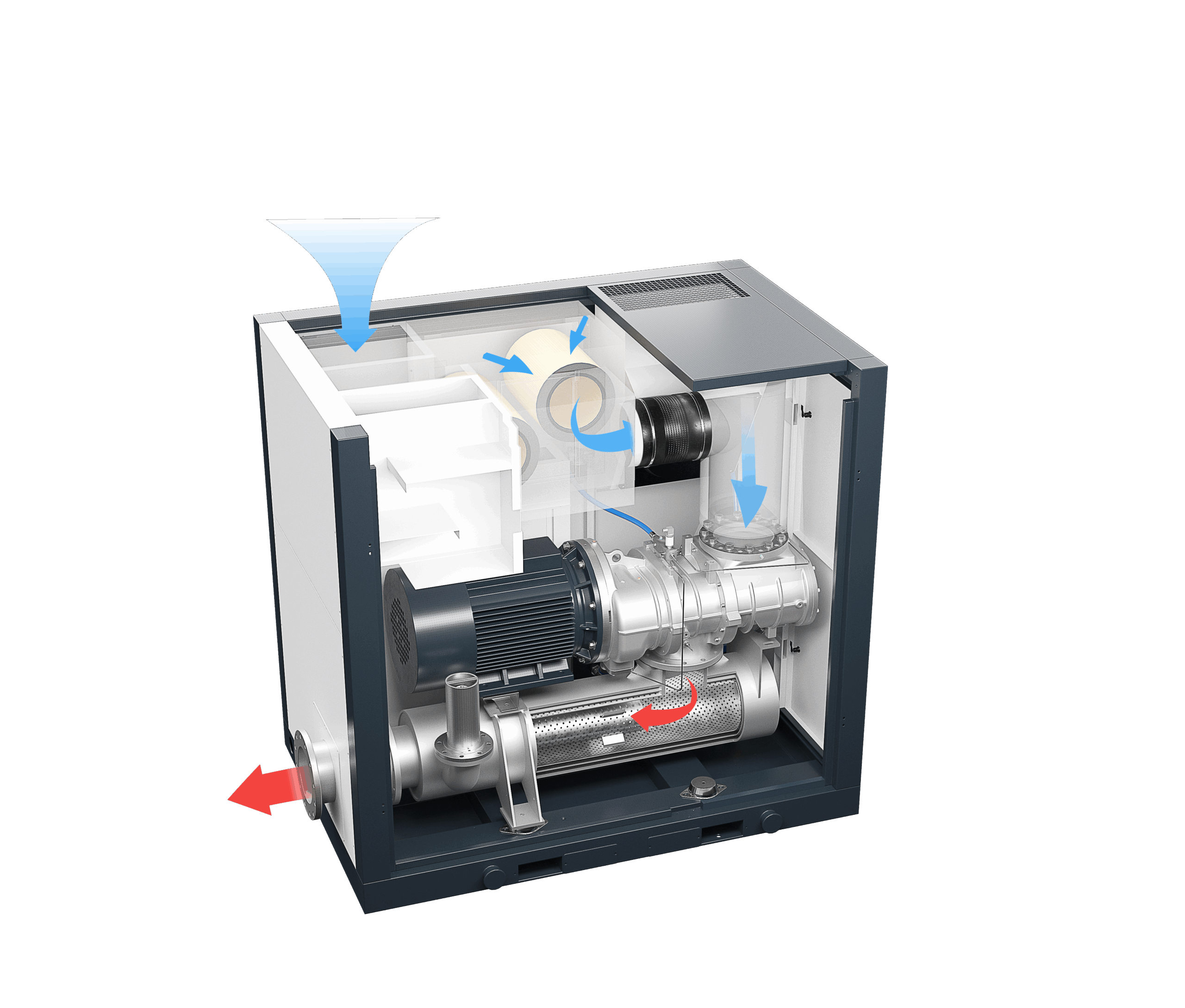

Types of Positive Displacement Blowers

Rotary Lobe (Roots-Type) Blowers: Use non-contacting lobes to move air. Common in wastewater aeration, pneumatic conveying, and dust collection.

Helical Lobe Blowers: Twisted rotors reduce pulsation, noise, and improve efficiency over traditional Roots designs.

Rotary Screw Blowers: Internal compression delivers higher efficiency, lower discharge temperatures, and reduced energy use.

Liquid Ring Blowers: Utilize a liquid seal and are well suited for wet or contaminated gas streams.

Centrifugal Blowers

Centrifugal blowers use dynamic acceleration to move air and are commonly used in ventilation, HVAC, and large-volume air handling applications.

Service and Maintenance Considerations

Routine maintenance including oil changes, bearing inspections, vibration analysis, and alignment checks is critical for blower reliability and long service life.

Innovative Oil Solutions Blower Services

Innovative Oil Solutions services industrial blower systems, positive displacement blowers, and screw blowers across all major manufacturers. Our technicians provide inspections, repairs, and preventative maintenance to ensure reliable airflow and minimized downtime.