Air-Operated Diaphragm (AOD) Pumps Explained

Reliable Fluid Transfer for Demanding Industrial Applications

Air-operated diaphragm (AOD) pumps are widely used across industry because of their simplicity, reliability, and ability to handle challenging fluids. From corrosive chemicals and abrasive slurries to viscous products and shear-sensitive materials, AOD pumps provide safe, flexible pumping solutions where other pump technologies struggle.

Innovative Oil Solutions services air-operated diaphragm pumps across a wide range of industries, supporting all major manufacturers. Our technicians provide maintenance, repairs, and replacement solutions to keep fluid transfer systems operating safely, efficiently, and reliably.

What Is an Air-Operated Diaphragm (AOD) Pump?

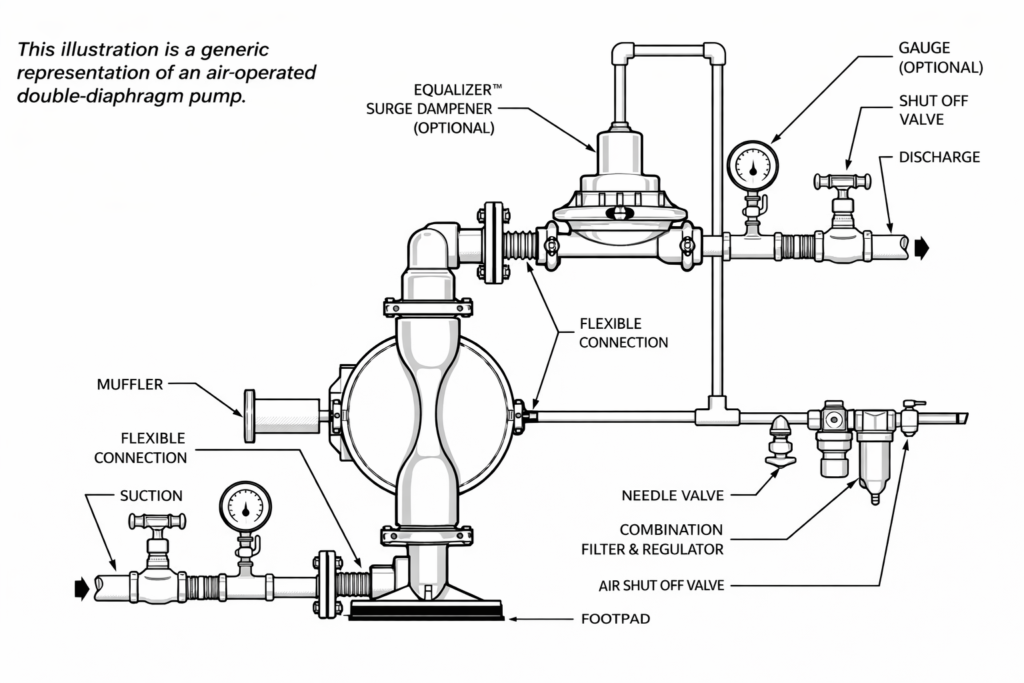

An AOD pump uses compressed air to move flexible diaphragms back and forth, creating suction and discharge cycles that transfer fluid. The pump contains two chambers separated by diaphragms, which are alternately pressurized by air to move fluid through check valves.

Key characteristics of AOD pumps include:

- No electric motor

- Self-priming capability

- Ability to run dry without damage

- Intrinsically safe operation

- Simple mechanical design

Because they are powered by air, AOD pumps are commonly used in hazardous or remote environments.

Why AOD Pumps Are Used in Industrial Applications

AOD pumps are chosen for applications where process flexibility and reliability are critical.

Common advantages include:

- Ability to handle corrosive, abrasive, and viscous fluids

- Safe operation in explosive or hazardous areas

- Gentle pumping of shear-sensitive products

- Simple maintenance with minimal tools

- Tolerance of solids-laden fluids

These features make AOD pumps a preferred solution across many industries.

Common Applications for AOD / Diaphragm Pumps

AOD pumps are used in a wide variety of industrial environments, including:

- Chemical processing and transfer

- Oil & gas and midstream operations

- Wastewater treatment and sludge handling

- Mining and slurry transfer

- Food and beverage processing

- Paints, coatings, and adhesives

- Pharmaceuticals and cosmetics

- Bulk fluid unloading and tank transfer

Their versatility allows a single pump design to support many different applications by changing materials and configurations.

Types of Diaphragm Materials and Pump Construction

Diaphragm Materials

Selecting the correct diaphragm material is critical for pump life and compatibility. Common materials include:

- PTFE (Teflon®) for chemical resistance

- Santoprene® for durability and flexibility

- Buna-N and EPDM for general-purpose applications

- Viton® for high-temperature or aggressive fluids

Pump Body Materials

AOD pumps are available in:

- Aluminum

- Stainless steel

- Cast iron

- Polypropylene

- PVDF and other engineered plastics

Proper material selection prevents chemical attack, premature failure, and contamination.

Air Supply Considerations for AOD Pumps

Because AOD pumps are air-driven, compressed air quality and control directly affect performance and operating cost.

Key considerations include:

- Clean, dry air to prevent valve sticking

- Proper air pressure regulation

- Flow control for pump speed adjustment

- Mufflers or silencers to reduce exhaust noise

Poor air quality increases downtime and accelerates wear on internal components.

Common AOD Pump Issues and Service Needs

Despite their rugged design, AOD pumps require routine service to remain reliable.

Typical maintenance and repair needs include:

- Diaphragm replacement

- Check valve inspection and replacement

- Air valve servicing

- Seal and O-ring replacement

- Leak and performance troubleshooting

Running pumps beyond recommended cycles or with incompatible materials is a leading cause of premature failure.

Service vs Replacement: Knowing When to Act

In many cases, AOD pumps can be economically rebuilt rather than replaced. However, replacement may be recommended when:

- Pump materials are incompatible with current fluids

- Air consumption is excessive compared to newer designs

- Repeated failures indicate application mismatch

- Efficiency improvements justify upgrading

Innovative Oil Solutions helps customers evaluate repair vs replacement to minimize lifecycle cost.

Safety and Compliance Benefits of AOD Pumps

AOD pumps are often selected for safety reasons:

- No electrical ignition source

- Intrinsically safe for hazardous locations

- Ability to stall without damage

- Reduced risk during upset conditions

These features make them ideal for volatile or regulated environments.

Innovative Oil Solutions: AOD Pump Service Experts

Innovative Oil Solutions services air-operated diaphragm pumps across demanding industrial applications. We support all major pump brands and configurations, providing:

- Preventative maintenance programs

- Emergency repairs

- Replacement and upgrade recommendations

- Air system optimization to reduce operating cost

Our goal is to keep fluid transfer systems operating safely, efficiently, and reliably—while minimizing unplanned downtime.

Keeping Fluid Transfer Reliable

AOD pumps are simple by design, but proper application, air quality, and maintenance are critical to long-term performance. With the right service partner, these pumps deliver reliable operation in environments where other technologies fail.

Innovative Oil Solutions provides the expertise and support needed to keep AOD pump systems running at peak performance.