Industrial Air Compressors Explained: Types, Applications, and Service Considerations

Compressed air is often referred to as the fourth utility in industrial operations—alongside electricity, water, and gas. Selecting the right air compressor technology has a direct impact on energy efficiency, reliability, maintenance costs, and overall plant uptime.

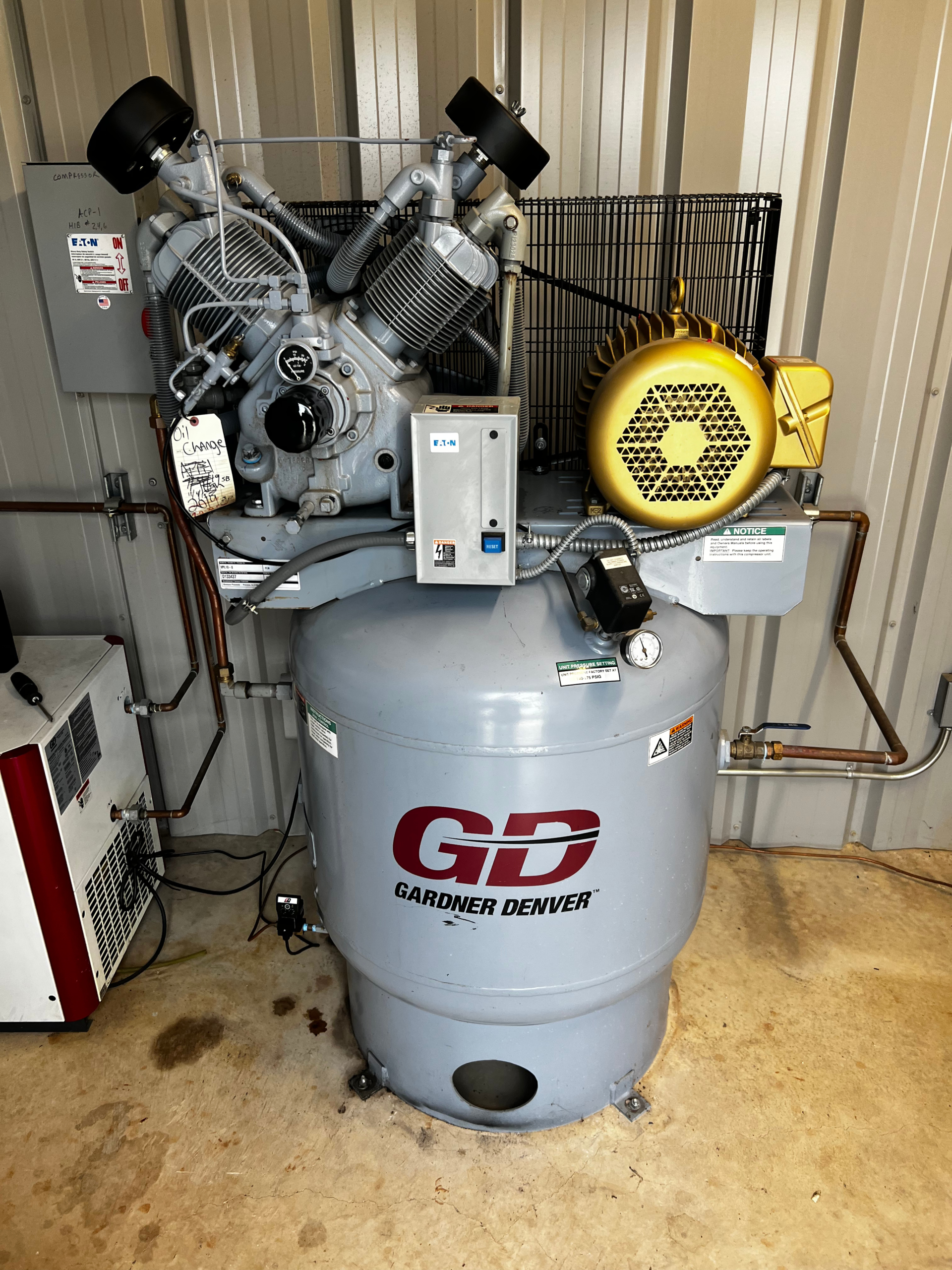

Reciprocating (Piston) Air Compressors

How They Work:

Reciprocating compressors use pistons driven by a crankshaft to compress air

within cylinders.

Applications:

Small to mid-sized manufacturing, automotive shops, intermittent duty applications.

Pros:

Lower cost, simple design, good for intermittent use.

Cons:

Noisy, higher maintenance, not ideal for continuous duty.

Service Considerations:

Frequent valve, ring, oil, and belt maintenance required.

Rotary Screw Air Compressors

How They Work:

Two intermeshing rotors compress air continuously, most commonly oil-flooded.

Applications:

Manufacturing plants, packaging, continuous-duty operations.

Pros:

Efficient, reliable, continuous airflow.

Cons:

Higher upfront cost, complex systems.

Service Considerations:

Oil, filter, separator changes and cooler cleaning are critical.

Scroll Air Compressors

How They Work:

Orbiting scrolls compress air without metal-to-metal contact.

Applications:

Medical, dental, labs, electronics.

Pros:

Quiet, oil-free, reliable.

Cons:

Limited capacity, higher cost per CFM.

Service Considerations:

Minimal wear parts, focus on filtration and electrical systems.

Centrifugal Air Compressors

How They Work:

High-speed impellers compress air dynamically.

Applications:

Large plants, refineries, high-volume demand.

Pros:

Oil-free, very high airflow, long life.

Cons:

High capital cost, part-load inefficiency.

Service Considerations:

Precision service including vibration and seal monitoring.

Oil-Flooded vs Oil-Free Compressors

Oil-Flooded:

Lower cost, efficient, but requires oil management and filtration.

Oil-Free:

No contamination risk, higher upfront and service costs, used in critical air applications.

How Innovative Oil Solutions Supports Your System

Innovative Oil Solutions provides comprehensive industrial air compressor sales and service for reciprocating, rotary screw, scroll, oil-free, and centrifugal compressors. Our factory-trained technicians support new installations, repairs, preventative maintenance, and parts sourcing.