Nitrogen and Oxygen Generation Systems: Applications, Technology, and ROI

Industrial facilities are increasingly adopting on-site nitrogen and oxygen generation to improve reliability, reduce operating costs, and eliminate dependence on delivered gas. When properly designed around the compressed air system, on-site generation provides fast return on investment while improving safety and supply security.

What Nitrogen Is Used For

• Inerting and blanketing of tanks and vessels

• Purging pipelines and process equipment

• Preventing oxidation and contamination

• Food and beverage packaging

• Oil & gas and petrochemical applications

• Fire and explosion risk reduction

What Oxygen Is Used For

• Wastewater treatment and aeration systems

• Combustion enhancement in furnaces and boilers

• Glass, steel, and metals manufacturing

• Chemical oxidation processes

• Medical and laboratory environments

How Compressed Air Enables Gas Generation

Nitrogen and oxygen generators separate gases from ambient air using compressed air as the feed source. System performance and operating cost depend heavily on compressor sizing, air treatment quality, and energy efficiency.

Types of Nitrogen and Oxygen Generation Technologies

Pressure Swing Adsorption (PSA): Uses adsorption media to separate nitrogen or oxygen. Capable of high purity but requires careful consideration of compressed air consumption due to purge and regeneration losses.

Membrane Generation: Uses selective permeability membranes to separate nitrogen. Lower purity capability but simpler operation and lower air consumption.

Critical Consideration: Air Consumption in PSA Systems

Pressure swing systems consume significantly more compressed air than their nitrogen or oxygen output suggests. Air is used for both production and regeneration cycles, making proper compressor sizing essential to achieving expected purity and ROI.

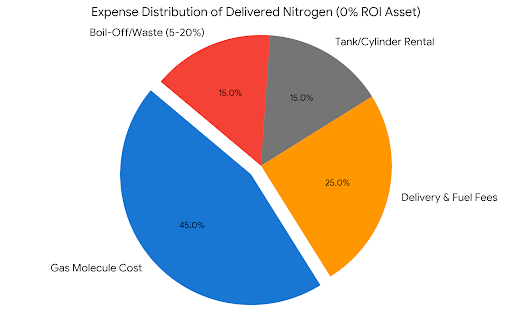

Delivered Nitrogen and Oxygen: True Cost and Limitations

• Transportation and fuel costs

• Driver labor and logistics

• Bulk tank rental and inspection

• Boil-off losses during storage

• Supply chain disruptions and emergency delivery premiums

• Cryogenic and asphyxiation safety risks

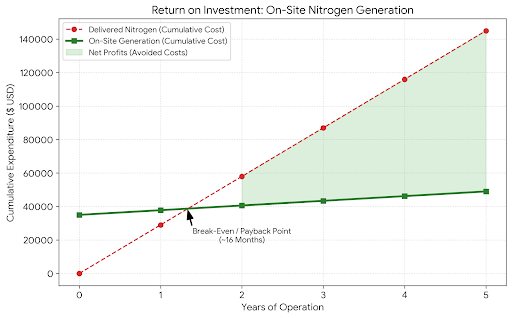

On-Site Generation ROI and Payback

Facilities switching from tanker-delivered gas to on-site generation typically see ROI within 12–36 months, with high-consumption sites achieving payback in less than 12 months. Long-term cost savings often exceed 50–70%.

Why On-Site Generation Delivers Faster ROI

• Eliminates delivery and transportation charges

• Removes vendor markups and storage losses

• Converts gas cost into predictable utility expense

• Improves safety and reduces compliance burden

• Enhances reliability and uptime

System Design Determines ROI Success

Achieving expected ROI depends on proper system engineering, including air compressor sizing, dryer and filtration selection, storage design, and control strategy. Poorly designed systems fail to meet purity and efficiency targets.

Innovative Oil Solutions: Complete Gas Generation Systems

Innovative Oil Solutions designs, installs, and services nitrogen and oxygen generation systems integrated with compressed air infrastructure. Our system-level approach ensures performance, reliability, and long-term cost savings while eliminating dependence on delivered gas.